Taking the pressure off the pump users

Many industries use high-pressure water systems to improve their equipment cleaning capacity and sterilize machinery or other items that require it. But they can be prone to technical issues, depending upon the industry and water quality. Experts in the Pumps Australia service centre often receive queries from clients with faulty systems. Some have seen their diesel-fired boilers fail, while others complain that their hot and cold pressure cleaner no longer works.

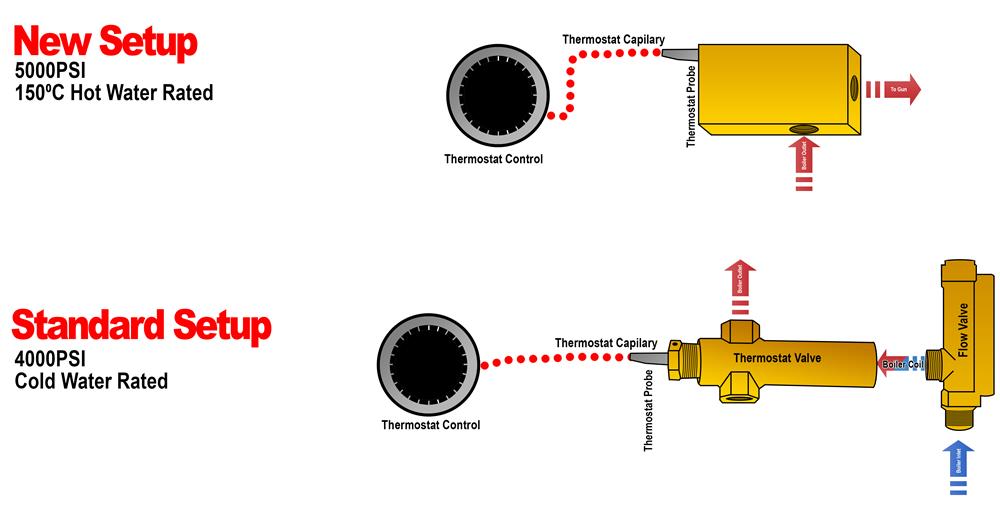

Never one to shirk a challenge, Pumps Australia Managing Director John Warne and his team have developed a Smart Flow switch and thermostat holder. To minimize potential problems, they combined the two elements to develop an all-in-one piece that is improving the capacity of high-pressure hot water systems.

The Problem

Pressure cleaner owners are limited in how they can maintain their machines. John says they should change the oil in the HP Pump regularly – 15W 40 semi-synthetic is good and readily available.

“They also need to ensure the filtered diesel fuel is clean and watch out for water condensation build-up in diesel fuel reservoir or leaks on hoses and spray guns,” he says. “How long your pressure cleaner lasts will also depend on its application.

“Cleaners can have a long life in the food and beverage industry, where water supply is generally good. The water is slightly harsher for those using them on farms and local councils in rural areas, as it might come from water tanks or bores.” Hardest hit when it comes to reliability are mining companies and contractors, due to harsh operating conditions that may include iron oxide and high calcium levels in the water. Over time, this can build up on the inside of the boiler coils, causing them to become blocked. Acid flushing is the only way to clean this. Another potential problem is the quality of flow switches which come in many different designs.

So how do you decide which one works best for you?

The Research

Pumps Australia’s research has found some alarming results.

“When some types of flow switches are used, the iron oxide in the water can build up on the magnetic flow switching valve, which stops the boiler firing up,” John explains. “When the shuttle valve sticks in the open position, catastrophic failure to the boiler will happen. “When the boiler is left to operate in the ‘on’ position with no water flow, the water inside the boiler coil/tube will become so hot the water will flash off to steam causing great internal pressure and blow a hole in the tube.”

The Solution

John recommends that rural councils and those using high-pressure water cleaners in the food and beverage industries remove and clean existing flow switches and have them function tested once a year, or better still replaced.

“Contractors and mining companies should check the components every six months and replace them every 12 months to maintain the equipment’s operating life,” he says.

They can also use a Smart Flow switch and thermostat holder, which combines both functions to simplify the system and potentially improve its lifespan.

Pumps Australia spent many months testing and developing the unique component for its Industrial range of hot and cold pressure cleaners, including petrol, diesel, and electric driven units. It can also be retrofitted to existing comparable hot and cold units.

“It has full operating stroke without the oxide issue being a problem,” John says. “The switch can be fitted to the cold water or hot water side of the boiler and rated to 150C.

“This device is located in the boiler’s hot water outlet and has the dual function of flow switch and thermo-well for the thermostat setting. It is easy to install and maintain and enhances the performance and longevity of our hot water machines.”